Industrial automation systems require reliable and efficient communication technologies to ensure seamless operations across complex networks. Among the various communication methods available, low-voltage carrier technology has emerged as a transformative solution for modern industrial applications. This technology leverages existing electrical infrastructure to transmit data signals, offering manufacturers and facility operators a cost-effective approach to implementing sophisticated automation systems without extensive rewiring or infrastructure modifications.

The adoption of low-voltage carrier systems in industrial environments has accelerated significantly due to their ability to integrate with existing power distribution networks. Manufacturing facilities, processing plants, and automated warehouses increasingly rely on these systems to maintain continuous communication between control systems, sensors, and actuators. The technology provides a robust foundation for Industry 4.0 initiatives, enabling real-time data exchange and remote monitoring capabilities that enhance operational efficiency and reduce maintenance costs.

Fundamental Principles of Low-Voltage Carrier Technology

Signal Transmission Mechanisms

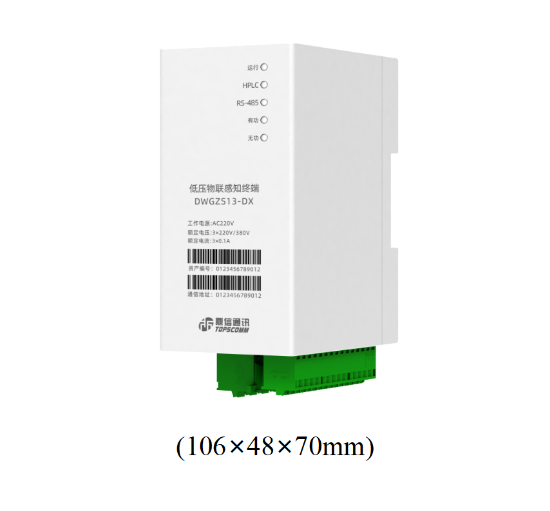

Low-voltage carrier technology operates by superimposing high-frequency data signals onto existing low-voltage power lines, typically operating within the frequency range of 9 to 500 kHz. The carrier signals are modulated to carry digital information while remaining separate from the main power frequency, ensuring that data transmission does not interfere with electrical equipment operation. Advanced filtering techniques prevent signal degradation and maintain data integrity across various network topologies and environmental conditions.

The modulation schemes employed in low-voltage carrier systems include Frequency Shift Keying (FSK), Phase Shift Keying (PSK), and Orthogonal Frequency Division Multiplexing (OFDM). These techniques enable multiple communication channels to operate simultaneously on the same power line infrastructure, maximizing bandwidth utilization and supporting concurrent data streams from various industrial devices and sensors.

Infrastructure Integration Capabilities

Modern low-voltage carrier implementations seamlessly integrate with existing electrical distribution systems through specialized coupling devices and signal conditioning equipment. These components ensure optimal signal quality while maintaining electrical safety standards and regulatory compliance. The technology supports both point-to-point and multi-point communication architectures, allowing flexible network configurations that adapt to diverse industrial requirements and facility layouts.

Installation procedures for low-voltage carrier systems require minimal disruption to ongoing operations, as the technology utilizes existing wiring infrastructure. Signal repeaters and amplifiers can be strategically positioned to extend communication range and overcome signal attenuation issues common in large industrial facilities with extensive cable runs and multiple distribution panels.

Enhanced Operational Efficiency Through Streamlined Communication

Real-Time Data Exchange Capabilities

Low-voltage carrier technology enables instantaneous communication between distributed control systems, facilitating real-time monitoring and control of industrial processes. This capability allows operators to receive immediate feedback from remote sensors, actuators, and monitoring devices, enabling rapid response to changing operational conditions and potential equipment malfunctions. The technology supports data rates sufficient for transmitting critical process parameters, alarm signals, and diagnostic information without latency issues.

The real-time communication capabilities of low-voltage carrier systems extend to complex automation scenarios involving coordinated equipment operation and synchronized process control. Manufacturing lines benefit from precise timing coordination between robotic systems, conveyor controls, and quality inspection equipment, resulting in improved production throughput and reduced waste generation.

Centralized Monitoring and Control Systems

Implementation of low-voltage carrier communication enables the development of centralized monitoring and control architectures that provide comprehensive visibility into facility operations. Operators can access real-time data from distributed sensors and control devices through unified human-machine interfaces, simplifying system management and reducing the need for personnel to physically inspect remote equipment locations.

The centralized approach facilitated by low-voltage carrier technology supports advanced analytics and predictive maintenance strategies. Historical data collection and analysis capabilities enable facility managers to identify performance trends, optimize energy consumption, and schedule maintenance activities based on actual equipment condition rather than predetermined schedules.

Cost-Effectiveness and Infrastructure Optimization

Reduced Installation and Maintenance Expenses

Low-voltage carrier systems significantly reduce infrastructure installation costs by eliminating the need for dedicated communication cables throughout industrial facilities. Existing power distribution networks serve dual purposes, carrying both electrical power and communication signals, resulting in substantial savings on cable procurement, installation labor, and conduit systems. This approach particularly benefits retrofit applications where adding new communication infrastructure would require extensive facility modifications.

Maintenance costs associated with low-voltage carrier implementations remain minimal due to the robust nature of the technology and its integration with existing electrical systems. The reduced number of physical connections and cable runs decreases potential failure points, while built-in diagnostic capabilities enable proactive identification of communication issues before they impact operations.

Scalability and Future-Proofing Advantages

The inherent scalability of low-voltage carrier technology allows industrial facilities to expand communication networks incrementally without major infrastructure investments. Additional devices and monitoring points can be integrated into existing networks by simply connecting them to available power outlets or distribution points, providing exceptional flexibility for growing operations and changing automation requirements.

Future technology upgrades and protocol enhancements can be implemented through software updates and equipment replacement without requiring extensive rewiring or infrastructure modifications. This capability ensures that low-voltage carrier investments remain relevant and valuable as industrial automation technologies continue to evolve and improve.

Enhanced Reliability and System Resilience

Robust Signal Quality Management

Low-voltage carrier systems incorporate advanced error detection and correction mechanisms that maintain communication reliability even in challenging industrial environments. Automatic repeat request protocols and forward error correction techniques ensure data integrity during transmission, while adaptive modulation schemes optimize signal quality based on real-time channel conditions and interference levels.

The technology demonstrates exceptional resilience against electromagnetic interference commonly present in industrial settings, including motor drives, welding equipment, and high-power switching devices. Sophisticated filtering and signal processing algorithms isolate carrier signals from electrical noise, maintaining consistent communication performance across diverse operational conditions.

Redundancy and Fault Tolerance Features

Modern low-voltage carrier implementations support multiple communication paths and redundant signal routing to ensure continued operation during equipment failures or maintenance activities. Alternative routing capabilities automatically redirect communication traffic around failed network segments, maintaining critical system connectivity and preventing operational disruptions.

Built-in diagnostic and monitoring functions continuously assess network performance and signal quality, providing early warning of potential issues before they impact system reliability. These capabilities enable proactive maintenance strategies and minimize unplanned downtime associated with communication system failures.

Security and Data Protection Considerations

Encryption and Access Control Mechanisms

Low-voltage carrier systems implement comprehensive security measures to protect sensitive industrial data and prevent unauthorized access to critical control systems. Advanced encryption protocols secure data transmission across power line networks, while authentication mechanisms ensure that only authorized devices can participate in communication sessions. These security features address growing concerns about cybersecurity threats targeting industrial automation systems.

Access control capabilities enable network administrators to define communication privileges and restrict device access based on operational requirements and security policies. Role-based access control and device authentication prevent unauthorized modifications to critical system parameters while maintaining operational flexibility for legitimate users and maintenance personnel.

Network Isolation and Segmentation Capabilities

The physical characteristics of low-voltage carrier technology provide inherent network isolation advantages compared to wireless communication systems. Power line networks remain contained within facility boundaries, reducing exposure to external security threats and unauthorized access attempts. Network segmentation capabilities further enhance security by isolating critical control systems from administrative networks and external connections.

Virtual network creation within low-voltage carrier systems enables logical separation of different operational areas or security zones without requiring physical network segregation. This capability supports compliance with industrial security standards and regulatory requirements while maintaining efficient resource utilization and simplified network management.

Applications Across Industrial Sectors

Manufacturing and Production Environments

Manufacturing facilities extensively utilize low-voltage carrier technology for connecting distributed control systems, sensor networks, and production monitoring equipment. The technology enables seamless integration of quality control systems, environmental monitoring devices, and safety equipment throughout production areas. Automotive assembly plants, food processing facilities, and pharmaceutical manufacturing operations benefit from the reliable communication capabilities and minimal installation requirements.

Production line optimization relies heavily on low-voltage carrier systems to coordinate equipment operation and maintain synchronization between manufacturing processes. The technology supports real-time adjustment of production parameters based on quality measurements and throughput requirements, resulting in improved product consistency and reduced waste generation.

Energy and Utility Applications

Power generation facilities and utility distribution systems leverage low-voltage carrier technology for substation automation, protective relay coordination, and grid monitoring applications. The technology enables reliable communication between geographically distributed equipment while utilizing existing power infrastructure, reducing installation costs and improving system reliability.

Smart grid implementations benefit significantly from low-voltage carrier systems, which facilitate two-way communication between utility operators and distributed energy resources. Advanced metering infrastructure, demand response systems, and renewable energy integration rely on the robust communication capabilities provided by modern low-voltage carrier implementations.

Implementation Best Practices and Considerations

Network Planning and Design Strategies

Successful low-voltage carrier implementation requires comprehensive network planning that considers facility electrical infrastructure, communication requirements, and environmental factors. Signal propagation analysis helps identify optimal coupling locations and repeater placement to ensure adequate coverage throughout the facility. Load impedance matching and signal conditioning requirements must be evaluated to maintain optimal communication performance.

Network topology design should account for future expansion requirements and equipment additions to prevent communication bottlenecks and performance degradation. Hierarchical network structures and strategic segmentation enable efficient traffic management and simplified troubleshooting procedures when issues arise.

Integration with Existing Systems

Low-voltage carrier systems must be carefully integrated with existing automation and control systems to ensure compatibility and optimal performance. Protocol translation and gateway devices may be required to bridge communication between legacy equipment and modern carrier-based networks. Comprehensive testing and commissioning procedures validate system functionality and identify potential integration issues before full operational deployment.

Staff training and documentation are essential components of successful low-voltage carrier implementation. Maintenance personnel require understanding of both electrical and communication system principles to effectively troubleshoot and maintain hybrid power-communication networks. Proper documentation ensures consistent installation practices and facilitates future system modifications and upgrades.

FAQ

How does low-voltage carrier technology compare to traditional communication methods in terms of reliability?

Low-voltage carrier technology offers superior reliability compared to many traditional communication methods due to its utilization of existing electrical infrastructure and built-in redundancy capabilities. Unlike wireless systems that can suffer from interference and signal blockage, or dedicated cable systems that require extensive physical infrastructure, low-voltage carrier systems leverage the robust nature of power distribution networks. The technology incorporates advanced error correction, automatic retransmission protocols, and alternative routing capabilities that maintain communication even when individual network segments experience issues.

What are the typical data transmission rates achievable with modern low-voltage carrier systems?

Modern low-voltage carrier systems can achieve data transmission rates ranging from several kilobits per second to multiple megabits per second, depending on the specific technology implementation and network conditions. Industrial applications typically operate within the range of 9.6 kbps to 1 Mbps, which is sufficient for most automation and monitoring requirements including real-time process data, alarm signals, and diagnostic information. Advanced implementations utilizing OFDM modulation and improved signal processing can achieve higher data rates suitable for video transmission and large file transfers.

Can low-voltage carrier systems operate effectively in environments with high electrical noise?

Yes, low-voltage carrier systems are specifically designed to operate effectively in industrial environments with significant electrical noise from motors, drives, and switching equipment. The technology employs sophisticated signal processing algorithms, adaptive filtering, and multiple modulation schemes to maintain communication quality despite electromagnetic interference. Frequency selection capabilities allow the system to avoid heavily congested frequency bands, while error correction mechanisms ensure data integrity even when signal-to-noise ratios are challenging.

What maintenance requirements are associated with low-voltage carrier communication systems?

Low-voltage carrier systems require minimal maintenance due to their integration with existing electrical infrastructure and solid-state electronic components. Routine maintenance typically involves periodic inspection of coupling devices, verification of signal quality parameters, and software updates for communication modules. Unlike traditional communication cables that may require physical inspection and replacement, low-voltage carrier systems benefit from the inherent reliability of power distribution networks and built-in diagnostic capabilities that provide early warning of potential issues before they impact operations.

Table of Contents

- Fundamental Principles of Low-Voltage Carrier Technology

- Enhanced Operational Efficiency Through Streamlined Communication

- Cost-Effectiveness and Infrastructure Optimization

- Enhanced Reliability and System Resilience

- Security and Data Protection Considerations

- Applications Across Industrial Sectors

- Implementation Best Practices and Considerations

-

FAQ

- How does low-voltage carrier technology compare to traditional communication methods in terms of reliability?

- What are the typical data transmission rates achievable with modern low-voltage carrier systems?

- Can low-voltage carrier systems operate effectively in environments with high electrical noise?

- What maintenance requirements are associated with low-voltage carrier communication systems?