Modern industrial environments demand robust and versatile communication solutions that can seamlessly integrate multiple protocols while maintaining reliability under harsh conditions. As manufacturing facilities evolve into smart factories and industrial automation becomes increasingly sophisticated, the need for flexible communication infrastructure has never been more critical. Traditional single-protocol communication systems often fall short of meeting the diverse connectivity requirements of today's interconnected industrial landscape. This growing complexity has led to the widespread adoption of dual mode communication modules, which offer the flexibility to support multiple communication standards within a single device, providing manufacturers with unprecedented connectivity options and operational efficiency.

Understanding Dual Mode Communication Technology

Protocol Flexibility and Integration Capabilities

Dual mode communication modules represent a significant advancement in industrial connectivity, enabling devices to operate across multiple communication protocols simultaneously or switch between them as needed. These sophisticated modules typically support combinations of wireless standards such as Wi-Fi and Bluetooth, or wired protocols like Ethernet and serial communication. The ability to maintain multiple communication pathways ensures continuous connectivity even when one protocol experiences interference or network issues. This redundancy is particularly valuable in mission-critical industrial applications where communication failure could result in costly downtime or safety hazards.

The integration capabilities of dual mode modules extend beyond simple protocol switching, offering intelligent routing and protocol translation features. Advanced modules can automatically select the most appropriate communication path based on signal strength, network congestion, or application requirements. This intelligent switching capability optimizes network performance while minimizing latency and power consumption, making these modules ideal for applications requiring real-time data transmission and precise control.

Hardware Architecture and Design Considerations

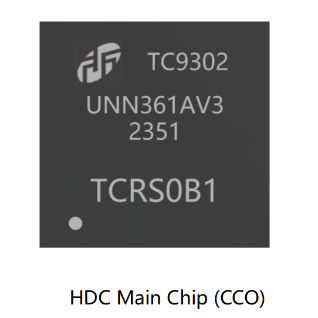

The hardware architecture of dual mode communication modules incorporates specialized chipsets and antenna designs that can efficiently handle multiple radio frequencies and signal types. These modules typically feature dedicated processing units for each communication protocol, ensuring optimal performance without interference between different communication standards. The compact design allows for easy integration into existing industrial equipment while providing the necessary shielding and filtering to maintain signal integrity in electromagnetically noisy industrial environments.

Power management represents another critical aspect of dual mode module design, as these devices must balance the energy requirements of multiple communication interfaces while maintaining extended operational lifecycles. Advanced power management algorithms can dynamically adjust transmission power and duty cycles based on communication needs, significantly extending battery life in portable applications while maintaining reliable connectivity throughout extended operational periods.

Critical Applications in Industrial Environments

Factory Automation and Control Systems

In modern factory automation systems, dual mode communication modules serve as the backbone for coordinating complex manufacturing processes that require seamless data exchange between programmable logic controllers, human-machine interfaces, and enterprise resource planning systems. These modules enable real-time monitoring and control of production lines while simultaneously providing connectivity for maintenance scheduling and quality assurance systems. The ability to maintain both local control networks and enterprise-level communications ensures that production data flows efficiently from the shop floor to management systems without compromising operational security or performance.

The implementation of dual mode communication in factory automation also supports the growing trend toward predictive maintenance and Industry 4.0 initiatives. By providing multiple communication pathways, these modules enable continuous monitoring of equipment health parameters while maintaining critical control functions. This dual capability allows maintenance teams to access diagnostic data remotely while ensuring that production operations continue uninterrupted, ultimately reducing maintenance costs and improving overall equipment effectiveness.

Process Monitoring and Data Acquisition

Process industries such as chemical manufacturing, oil and gas, and power generation rely heavily on distributed monitoring systems that require robust and redundant communication capabilities. Dual mode communication modules provide the necessary reliability for transmitting critical process data while offering backup communication paths in case of primary network failures. These modules can simultaneously handle high-priority alarm signals through one communication channel while managing routine data logging and historical trending through another protocol, ensuring that safety-critical information always reaches control room operators without delay.

The versatility of dual mode modules also enables the integration of legacy monitoring equipment with modern digital infrastructure. Many industrial facilities operate a mix of older analog instruments and newer digital sensors, requiring communication solutions that can bridge these different technologies effectively. Dual mode modules can maintain compatibility with existing fieldbus networks while providing modern wireless connectivity for mobile maintenance tools and remote monitoring applications.

Technical Advantages and Performance Benefits

Enhanced Reliability Through Redundancy

The primary technical advantage of dual mode communication modules lies in their ability to provide communication redundancy without requiring separate hardware installations. This built-in redundancy significantly improves system reliability by ensuring that critical data transmission continues even when one communication path experiences interference, congestion, or hardware failure. Industrial environments are particularly susceptible to electromagnetic interference from heavy machinery, welding operations, and power systems, making this redundancy essential for maintaining consistent connectivity.

Beyond simple backup functionality, dual mode modules can implement sophisticated failover algorithms that automatically detect communication issues and seamlessly switch to alternative protocols without interrupting data flow. This intelligent failover capability is particularly valuable in applications requiring continuous monitoring or real-time control, where even brief communication interruptions could have serious consequences for safety or product quality.

Optimized Network Performance and Bandwidth Management

Dual mode communication modules enable intelligent bandwidth allocation by distributing different types of traffic across appropriate communication channels based on latency requirements and data volume. Time-critical control signals can be routed through low-latency protocols while bulk data transfers use higher-bandwidth connections, optimizing overall network performance. This traffic segregation prevents bandwidth-intensive operations from interfering with critical control functions, ensuring consistent system responsiveness.

The ability to operate multiple protocols simultaneously also enables load balancing across different network segments, preventing bottlenecks that could degrade system performance. Advanced modules can dynamically adjust traffic distribution based on real-time network conditions, automatically shifting loads to less congested communication paths while maintaining quality of service requirements for critical applications.

Implementation Strategies and Best Practices

Network Architecture Planning

Successful implementation of dual mode communication modules requires careful consideration of existing network infrastructure and future expansion requirements. Network architects must evaluate the compatibility between different communication protocols and ensure that security policies are consistently applied across all communication channels. The planning phase should include comprehensive site surveys to identify potential interference sources and coverage requirements for wireless protocols, ensuring optimal performance across the entire facility.

Integration with existing network management systems is crucial for maintaining visibility and control over dual mode communications. Network administrators need tools to monitor the status of all communication paths, track traffic patterns, and identify potential issues before they impact operations. Proper documentation of network topology and configuration parameters ensures that maintenance teams can effectively troubleshoot problems and implement necessary changes without disrupting ongoing operations.

Security Considerations and Protocol Management

The implementation of dual mode communication modules introduces additional security considerations, as each supported protocol may have different vulnerabilities and security requirements. Security architects must develop comprehensive policies that address authentication, encryption, and access control across all communication channels while maintaining the operational flexibility that makes dual mode modules valuable. Regular security assessments should evaluate the effectiveness of implemented safeguards and identify potential attack vectors that could compromise system integrity.

Protocol management becomes increasingly important as facilities deploy larger numbers of dual mode devices, requiring standardized configuration procedures and centralized management tools. Automated provisioning systems can ensure consistent security settings and protocol configurations across multiple devices while reducing the potential for human error during installation and maintenance procedures.

Future Trends and Technological Developments

Integration with Edge Computing Platforms

The convergence of dual mode communication modules with edge computing technologies is creating new opportunities for distributed intelligence in industrial applications. These integrated solutions can perform local data processing and analysis while maintaining multiple communication pathways for different types of information exchange. Edge-enabled dual mode modules can reduce network traffic by processing routine data locally while forwarding only critical alerts and summary information through primary communication channels.

Advanced edge computing capabilities also enable dual mode modules to implement sophisticated communication optimization algorithms that adapt to changing network conditions in real-time. Machine learning algorithms can analyze historical communication patterns to predict optimal protocol selection and traffic routing decisions, continuously improving network performance without requiring manual intervention from network administrators.

Enhanced Protocol Support and Standardization

Future developments in dual mode communication technology will likely include support for emerging industrial communication standards such as 5G networks, Time-Sensitive Networking, and advanced fieldbus protocols. These new capabilities will enable even greater flexibility in network design while maintaining backward compatibility with existing infrastructure. The evolution toward standardized industrial communication frameworks will simplify the integration of dual mode modules while ensuring interoperability between devices from different manufacturers.

The ongoing development of software-defined networking capabilities in industrial applications will also influence the evolution of dual mode communication modules. These modules will increasingly support dynamic protocol reconfiguration through software updates, enabling facilities to adapt their communication infrastructure to changing requirements without requiring hardware replacements or extensive reconfiguration procedures.

FAQ

What types of industrial applications benefit most from dual mode communication modules

Dual mode communication modules provide the greatest benefits in applications requiring high reliability, such as safety instrumented systems, critical process monitoring, and automated manufacturing lines. These modules are particularly valuable in environments with harsh electromagnetic conditions, distributed installations, or mixed legacy and modern equipment that requires different communication protocols.

How do dual mode modules handle security across different communication protocols

Modern dual mode communication modules implement protocol-specific security measures while maintaining centralized security management. Each communication channel can utilize appropriate encryption and authentication methods for its protocol, while the module coordinates security policies across all channels to prevent vulnerabilities and ensure consistent protection levels throughout the system.

Can dual mode communication modules operate both protocols simultaneously

Yes, most advanced dual mode communication modules can operate multiple protocols simultaneously, allowing them to handle different types of traffic concurrently. This capability enables load balancing, traffic segregation, and redundant communication paths while maintaining full functionality across all supported protocols without performance degradation.

What factors should be considered when selecting dual mode communication modules for industrial use

Key selection factors include protocol compatibility with existing infrastructure, environmental ratings for temperature and vibration resistance, power consumption requirements, and security features. Additional considerations include the module's ability to handle expected data volumes, latency requirements, and the availability of management tools for configuration and monitoring purposes.

Table of Contents

- Understanding Dual Mode Communication Technology

- Critical Applications in Industrial Environments

- Technical Advantages and Performance Benefits

- Implementation Strategies and Best Practices

- Future Trends and Technological Developments

-

FAQ

- What types of industrial applications benefit most from dual mode communication modules

- How do dual mode modules handle security across different communication protocols

- Can dual mode communication modules operate both protocols simultaneously

- What factors should be considered when selecting dual mode communication modules for industrial use